The Future of AI in Manufacturing: Revolutionizing the Industry

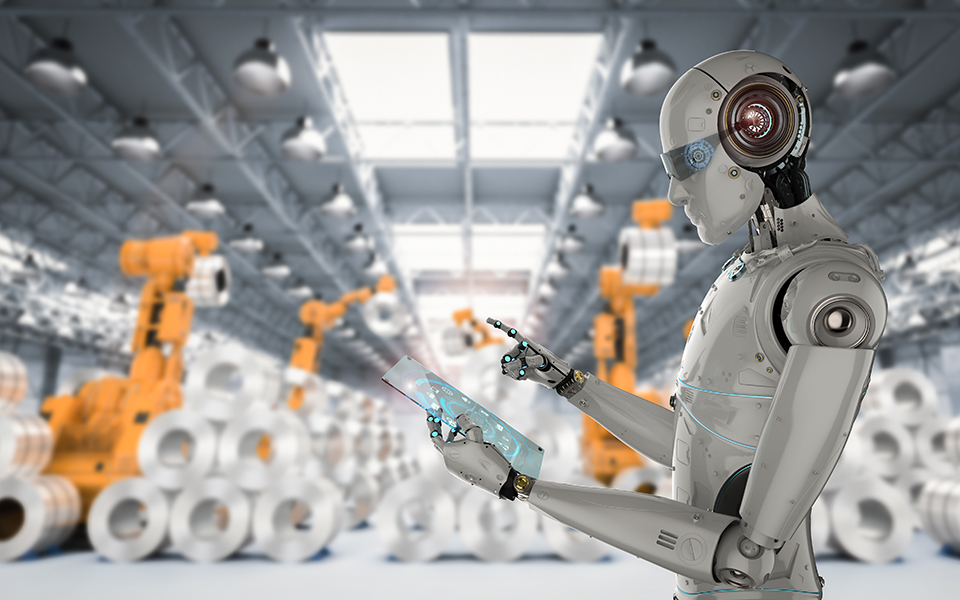

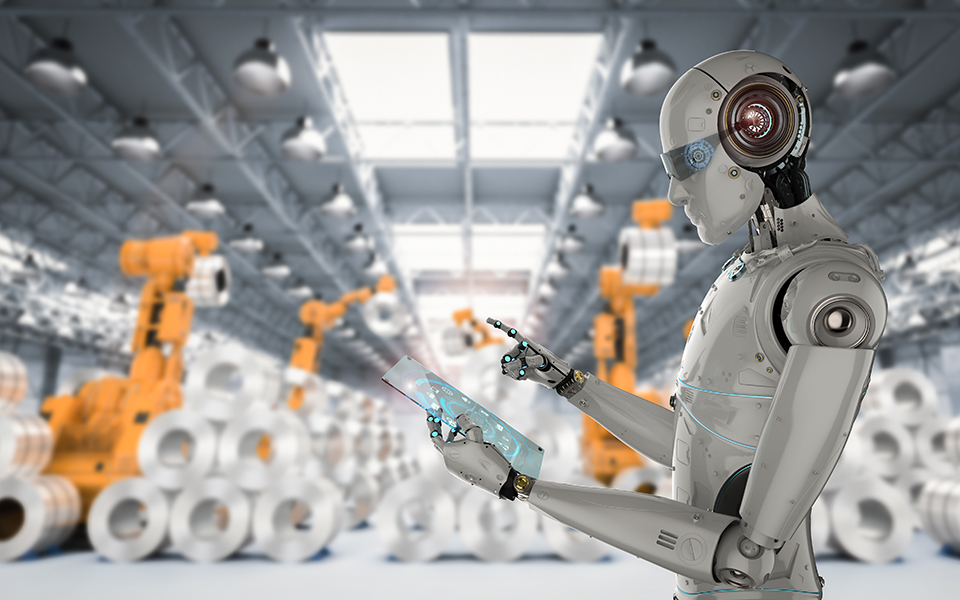

Artificial intelligence (AI) has been transforming various industries, and manufacturing is no exception. The use of AI in manufacturing has been increasing rapidly, and it is expected to play a crucial role in shaping the future of the industry. AI has the potential to revolutionize manufacturing by increasing efficiency, reducing costs, and improving product quality.

Current State of AI in Manufacturing

Currently, AI is being used in manufacturing to perform tasks such as predictive maintenance, quality control, and supply chain optimization. AI-powered machines are capable of learning from data and improving their performance over time, making them more efficient and accurate than traditional machines.

One of the most significant applications of AI in manufacturing is in predictive maintenance. AI algorithms can analyze data from sensors and machines to predict when equipment is likely to fail, allowing manufacturers to schedule maintenance and reduce downtime. This can lead to significant cost savings and improve overall efficiency.

AI is also being used in quality control to detect defects and anomalies in products. AI-powered machines can analyze images and data to identify defects, allowing manufacturers to take corrective action and improve product quality.

Future of AI in Manufacturing

As AI technology continues to evolve, we can expect to see even more innovative applications in manufacturing. Some of the future trends in AI in manufacturing include:

- Increased Use of Robotics: AI-powered robots will become more prevalent in manufacturing, performing tasks such as assembly, welding, and material handling.

- Autonomous Systems: AI-powered autonomous systems will enable machines to operate independently, making decisions and taking actions without human intervention.

- Digital Twins: AI-powered digital twins will allow manufacturers to create virtual replicas of their products and production processes, enabling real-time monitoring and optimization.

- Augmented Reality: AI-powered augmented reality will enable workers to access real-time data and instructions, improving their productivity and efficiency.

- Supply Chain Optimization: AI will continue to play a crucial role in supply chain optimization, enabling manufacturers to forecast demand, manage inventory, and optimize logistics.

Benefits of AI in Manufacturing

The benefits of AI in manufacturing are numerous, including:

- Increased Efficiency: AI can automate repetitive tasks, freeing up human workers to focus on more complex and creative tasks.

- Improved Product Quality: AI can detect defects and anomalies in products, enabling manufacturers to take corrective action and improve product quality.

- Reduced Costs: AI can help manufacturers reduce costs by optimizing production processes, reducing waste, and improving supply chain efficiency.

- Enhanced Customer Experience: AI can enable manufacturers to offer personalized products and services, improving customer satisfaction and loyalty.

- Competitive Advantage: The use of AI in manufacturing can provide a competitive advantage, enabling companies to stay ahead of their competitors and attract new customers.

Challenges of AI in Manufacturing

While AI has the potential to revolutionize manufacturing, there are also several challenges that need to be addressed, including:

- Data Quality: AI algorithms require high-quality data to function effectively, and poor-quality data can lead to inaccurate results.

- Cybersecurity: AI systems can be vulnerable to cyber attacks, which can compromise sensitive data and disrupt production.

- Workforce Augmentation: The use of AI in manufacturing may displace certain jobs, requiring workers to be retrained and upskilled.

- Regulatory Frameworks: There is a need for regulatory frameworks to be developed to govern the use of AI in manufacturing, ensuring that it is safe, transparent, and accountable.

- Integration with Existing Systems: AI systems may need to be integrated with existing systems, which can be complex and time-consuming.

Conclusion

The future of AI in manufacturing is promising, with the potential to increase efficiency, reduce costs, and improve product quality. However, there are also several challenges that need to be addressed, including data quality, cybersecurity, workforce augmentation, regulatory frameworks, and integration with existing systems.

As AI technology continues to evolve, we can expect to see even more innovative applications in manufacturing. Manufacturers who adopt AI early will be well-positioned to reap the benefits and stay ahead of their competitors.Ultimately, the use of AI in manufacturing has the potential to revolutionize the industry, enabling companies to produce high-quality products efficiently and effectively.

Recommendations

Based on the trends and benefits of AI in manufacturing, we recommend that manufacturers:

- Invest in AI Research and Development: Manufacturers should invest in AI research and development to stay ahead of the curve and reap the benefits of AI.

- Develop a Clear AI Strategy: Manufacturers should develop a clear AI strategy that aligns with their business goals and objectives.

- Upskill and Reskill the Workforce: Manufacturers should upskill and reskill their workforce to ensure that they have the necessary skills to work with AI systems.

- Address Cybersecurity Concerns: Manufacturers should address cybersecurity concerns by implementing robust security measures to protect their AI systems.

- Collaborate with Other Industries: Manufacturers should collaborate with other industries to share best practices and knowledge in AI adoption.

By following these recommendations, manufacturers can harness the power of AI to revolutionize their industry and stay ahead of the competition.