The Role of AI in Predictive Maintenance for Industries: Revolutionizing the Future of Maintenance

The industrial landscape is undergoing a significant transformation with the integration of artificial intelligence (AI) in various aspects of operations. One area where AI is making a substantial impact is in predictive maintenance. Predictive maintenance is a proactive approach to maintenance that involves using data and analytics to predict when equipment or machinery is likely to fail, allowing for timely repairs or replacement before a breakdown occurs. The role of AI in predictive maintenance is revolutionizing the way industries approach maintenance, reducing downtime, and increasing overall efficiency.

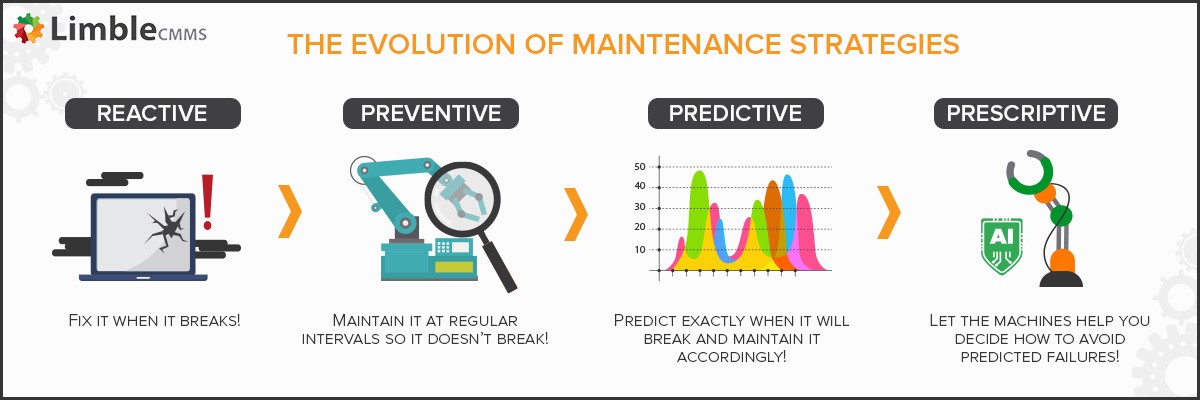

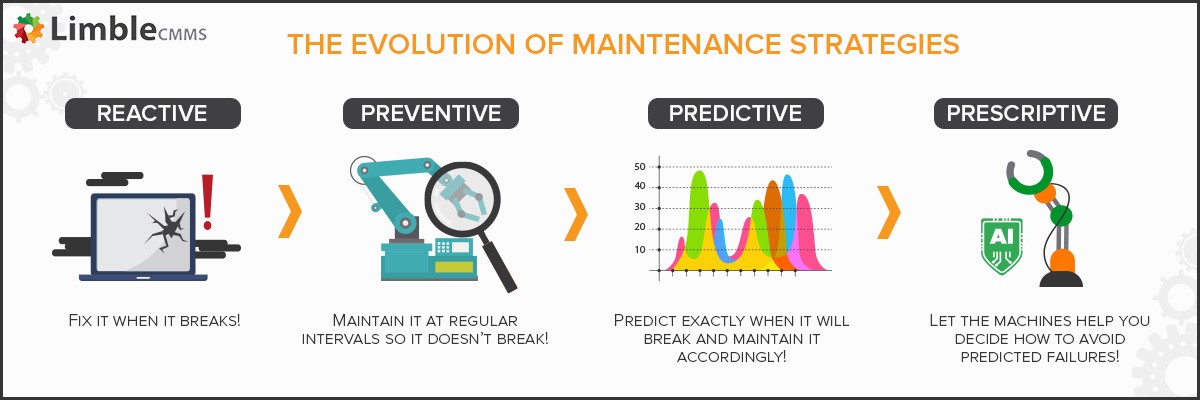

Traditional Maintenance Methods

Traditional maintenance methods, such as reactive and preventive maintenance, have been the norm in industries for decades. Reactive maintenance involves fixing equipment only when it breaks down, resulting in extended downtime and lost productivity. Preventive maintenance, on the other hand, involves scheduling maintenance at regular intervals, regardless of the equipment’s condition, which can lead to unnecessary repairs and waste of resources.

The limitations of these traditional methods have led to the adoption of predictive maintenance, which leverages advanced technologies like AI, machine learning, and IoT (Internet of Things) sensors to detect potential equipment failures before they occur.

How AI is Transforming Predictive Maintenance

AI is transforming predictive maintenance by analyzing vast amounts of data from various sources, including:

- Sensor data: IoT sensors are installed on equipment to capture real-time data on temperature, vibration, pressure, and other parameters.

- Historical data: Records of past equipment failures, maintenance activities, and repair history are used to identify patterns and trends.

- Real-time data: AI algorithms analyze real-time data from sensors and other sources to detect anomalies and predict potential failures.

AI algorithms, such as machine learning and deep learning, are applied to this data to identify patterns, trends, and correlations that can indicate potential equipment failures. These algorithms can also learn from the data and improve their predictions over time.

Benefits of AI-driven Predictive Maintenance

The implementation of AI-driven predictive maintenance offers numerous benefits to industries, including:

- Reduced downtime: Predictive maintenance enables industries to schedule maintenance during planned downtime, reducing unexpected breakdowns and increasing overall productivity.

- Increased efficiency: AI-driven predictive maintenance optimizes maintenance activities, reducing the time and resources required for repairs and maintenance.

- Cost savings: Predictive maintenance can reduce maintenance costs by up to 50% by identifying potential failures early and reducing the need for reactive maintenance.

- Improved safety: Predictive maintenance helps to identify potential safety hazards, reducing the risk of accidents and injuries.

- Extended equipment lifespan: Regular maintenance and timely repairs can extend the lifespan of equipment, reducing the need for costly replacements.

Applications of AI-driven Predictive Maintenance across Industries

AI-driven predictive maintenance is being adopted across various industries, including:

- Manufacturing: Predictive maintenance is used to optimize production lines, reduce downtime, and improve product quality.

- Oil and Gas: Predictive maintenance is used to detect potential equipment failures, reducing the risk of accidents and environmental disasters.

- Energy and Utilities: Predictive maintenance is used to optimize energy production and distribution, reducing power outages and improving grid reliability.

- Transportation: Predictive maintenance is used to monitor and maintain vehicles, reducing downtime and improving overall fleet efficiency.

- Healthcare: Predictive maintenance is used to monitor medical equipment, reducing downtime and improving patient care.

Challenges and Limitations of AI-driven Predictive Maintenance

While AI-driven predictive maintenance offers numerous benefits, there are also challenges and limitations to its adoption, including:

- Data quality: AI algorithms require high-quality data to make accurate predictions. Poor data quality can lead to inaccurate predictions and reduced effectiveness.

- Integration with existing systems: AI-driven predictive maintenance requires integration with existing maintenance management systems, which can be complex and time-consuming.

- Skills and training: Maintenance personnel require training and skills to work with AI-driven predictive maintenance systems, which can be a challenge for some organizations.

- Cybersecurity: AI-driven predictive maintenance systems require robust cybersecurity measures to prevent data breaches and unauthorized access.

Conclusion

The role of AI in predictive maintenance is revolutionizing the way industries approach maintenance. By leveraging AI algorithms and IoT sensors, industries can reduce downtime, increase efficiency, and improve overall productivity. While there are challenges and limitations to the adoption of AI-driven predictive maintenance, the benefits far outweigh the drawbacks. As the technology continues to evolve, we can expect to see increased adoption across industries, leading to a significant transformation in the way maintenance is approached.

In the future, AI-driven predictive maintenance is expected to become even more sophisticated, with the integration of additional technologies like augmented reality and 5G networks. As the technology advances, we can expect to see even more benefits, including:

- Real-time monitoring: AI-driven predictive maintenance will enable real-time monitoring of equipment, allowing for instant notifications of potential failures.

- Autonomous maintenance: AI algorithms will be able to autonomously schedule and perform maintenance activities, reducing the need for human intervention.

- Predictive analytics: AI algorithms will be able to predict not only when equipment is likely to fail but also the likelihood of failure, allowing for proactive measures to be taken.

The future of maintenance is arriving, and it’s being driven by AI. Industries that adopt AI-driven predictive maintenance will be at the forefront of this revolution, reaping the benefits of increased efficiency, reduced downtime, and improved productivity.