The Role of Technology in Predictive Maintenance

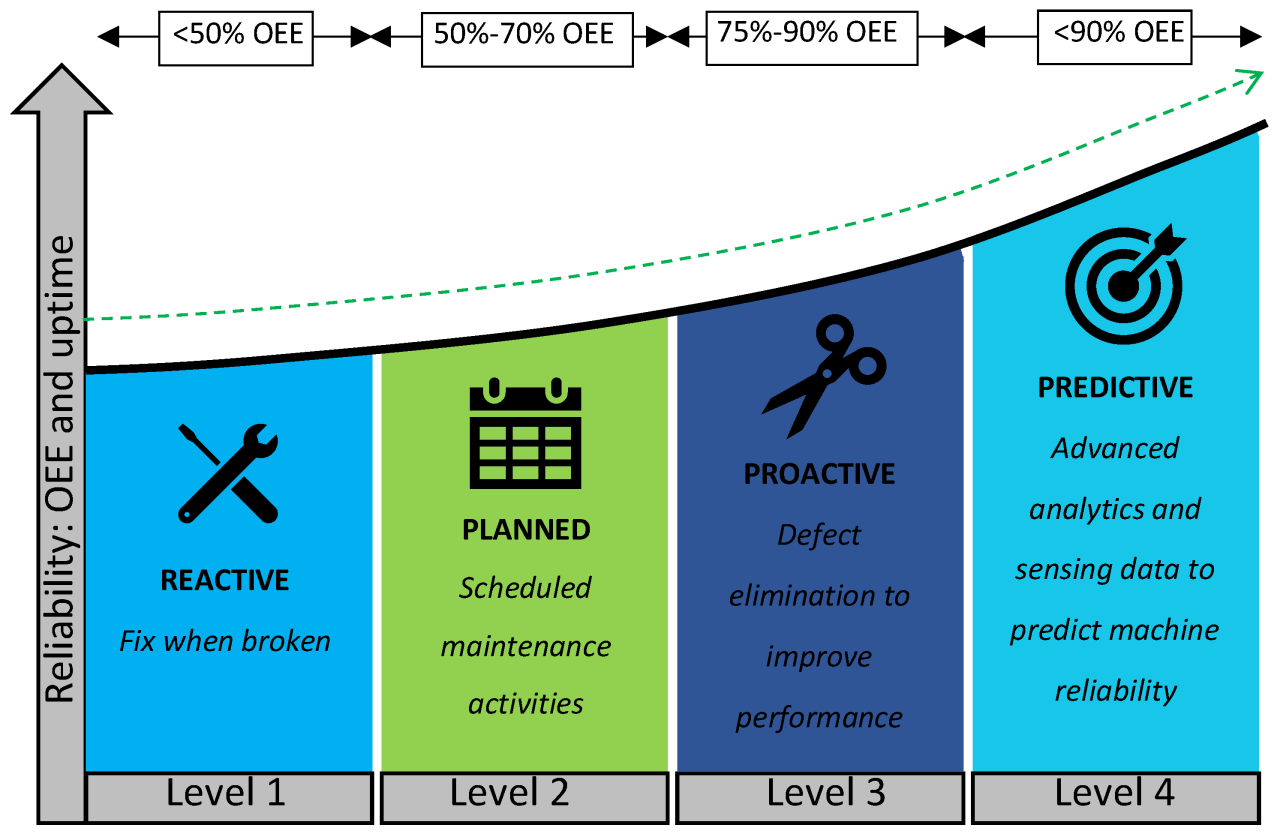

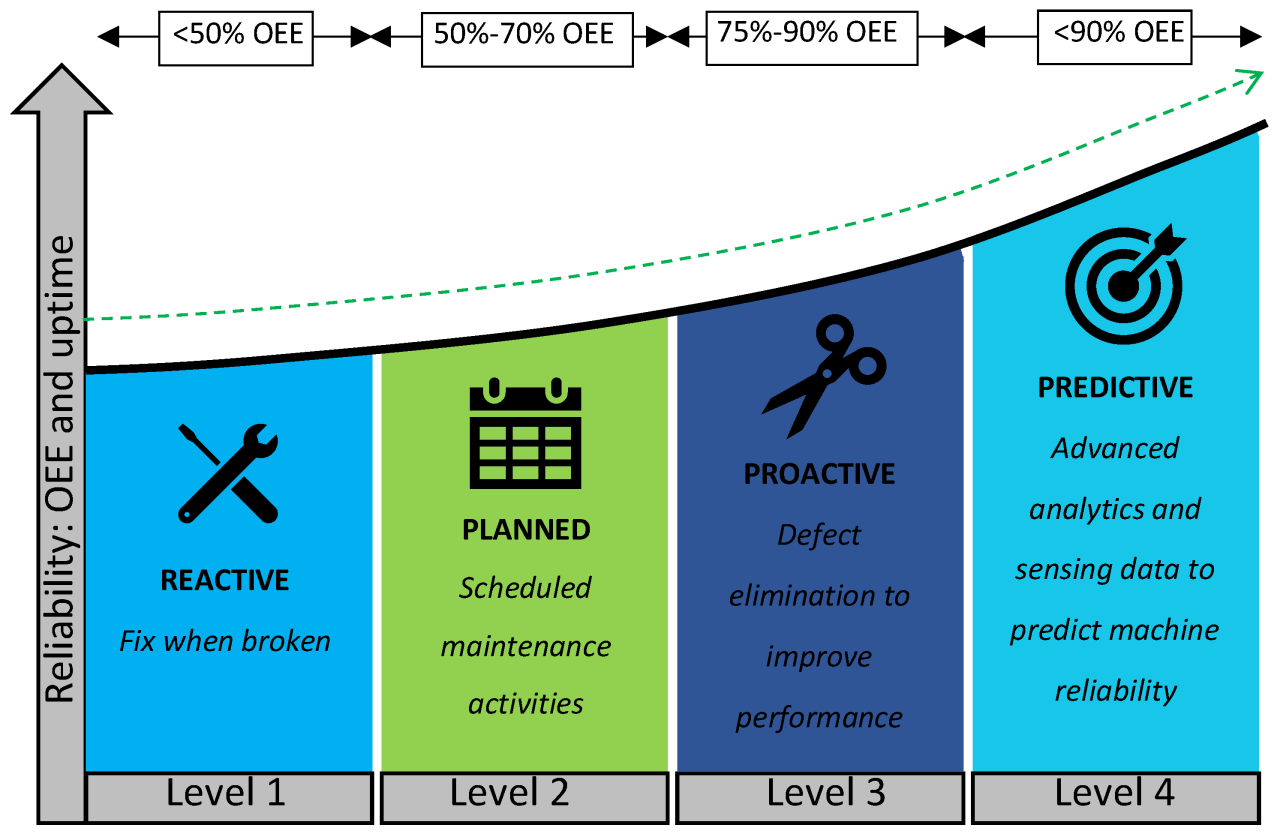

The traditional approach to maintenance, known as reactive maintenance, involves repairing or replacing equipment only after it has failed. This method can lead to costly downtime, reduced productivity, and increased safety risks. In contrast, predictive maintenance uses advanced technologies to detect potential equipment failures before they occur, allowing for proactive maintenance and minimizing unplanned downtime.

In recent years, the use of technology has revolutionized the field of predictive maintenance, enabling companies to improve maintenance efficiency, reduce costs, and enhance overall equipment reliability. This article will explore the role of technology in predictive maintenance, highlighting the key trends, tools, and techniques that are transforming the industry.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) refers to the integration of sensors, machines, and other devices connected to the internet, enabling real-time data exchange and analysis. In the context of predictive maintenance, IIoT plays a crucial role in collecting and processing vast amounts of data from equipment and sensors. This data is then analyzed using advanced algorithms and machine learning techniques to identify potential issues before they occur.

IIoT sensors can be attached to equipment to monitor temperature, vibration, pressure, and other parameters. This data is transmitted to the cloud or on-premise servers, where it is analyzed in real-time. Advanced analytics tools can detect anomalies, trends, and patterns in the data, enabling maintenance teams to respond proactively to potential issues.

Artificial Intelligence (AI) and Machine Learning (ML)

Artificial Intelligence (AI) and Machine Learning (ML) are key technologies in predictive maintenance. AI and ML algorithms can be trained on large datasets of equipment performance and maintenance records, enabling them to learn patterns and identify potential issues.

For example, an AI-powered predictive maintenance system can analyze sensor data from a motor and detect subtle changes in vibration patterns, indicating potential bearing failure. The system can then alert maintenance teams, who can schedule maintenance during a planned downtime, reducing the likelihood of an unplanned failure.

Condition-Based Maintenance

Condition-based maintenance involves monitoring equipment performance in real-time, using data from sensors and other sources. This approach enables maintenance teams to respond to changes in equipment condition, rather than following a fixed schedule.

Condition-based maintenance relies on advanced data analytics and AI to analyze equipment data and identify potential issues. For example, a gas turbine used in power generation can be equipped with sensors to monitor temperature, vibration, and pressure. Advanced analytics software can analyze this data in real-time, enabling maintenance teams to respond to changes in equipment condition and reduce the likelihood of an unplanned failure.

Cloud-Based Maintenance Platforms

Cloud-based maintenance platforms provide a centralized repository for maintenance data, enabling multiple stakeholders to access and analyze data remotely. These platforms can integrate with IIoT sensors, AI and ML algorithms, and other predictive maintenance tools, providing a holistic view of equipment performance and maintenance activities.

Cloud-based platforms also enable real-time collaboration and information sharing between maintenance teams, engineers, and operators. This can improve communication, reduce errors, and enhance overall maintenance efficiency.

Autonomous Maintenance

Autonomous maintenance involves the use of advanced technologies, such as AI, robotics, and drones, to perform maintenance tasks independently. For example, a drone equipped with sensors and AI algorithms can inspect equipment remotely, detecting potential issues and reporting back to maintenance teams.

Autonomous maintenance can reduce labor costs, improve efficiency, and enhance safety. Autonomous maintenance systems can also operate around the clock, enabling 24/7 monitoring and maintenance of critical equipment.

Augmented Reality (AR)

Augmented Reality (AR) technology is being used to enhance maintenance processes, particularly in industries such as aerospace, automotive, and energy. AR involves overlaying digital information onto real-world environments, enabling maintenance technicians to access detailed instructions, manuals, and real-time data on equipment performance.

AR can improve maintenance efficiency, reduce errors, and enhance safety. For example, an AR-powered maintenance system can provide technicians with step-by-step instructions on how to perform complex maintenance tasks, reducing the risk of human error.

Big Data Analytics

Big Data analytics involves the analysis of large and complex datasets to identify patterns, trends, and correlations. In predictive maintenance, big data analytics is used to analyze equipment performance data, maintenance records, and other sources of information.

Advanced analytics tools can analyze large datasets to identify potential issues, detect anomalies, and predict equipment failures. This enables maintenance teams to respond proactively to potential issues, reducing downtime and improving overall equipment reliability.

Cybersecurity

As predictive maintenance systems become more connected to the internet, they also become more vulnerable to cyber threats. Cybersecurity is a critical aspect of predictive maintenance, as a cyber attack can compromise the integrity of equipment and maintenance data.

Companies must implement robust cybersecurity measures, such as encryption, firewalls, and secure login protocols, to protect predictive maintenance systems from cyber threats.

Benefits of Technology in Predictive Maintenance

The use of technology in predictive maintenance offers numerous benefits, including:

- Improved Equipment Reliability: Predictive maintenance enables companies to detect potential equipment failures before they occur, reducing the likelihood of unplanned downtime and improving overall equipment reliability.

- Reduced Maintenance Costs: Predictive maintenance can reduce maintenance costs by enabling companies to schedule maintenance during planned downtime, reducing the need for costly repairs and replacements.

- Enhanced Safety: Predictive maintenance can improve safety by detecting potential safety risks, such as equipment failures, and enabling companies to take proactive measures to mitigate these risks.

- Increased Efficiency: Predictive maintenance can improve maintenance efficiency by automating routine maintenance tasks, reducing labor costs, and enabling technicians to focus on higher-value tasks.

- Improved Decision-Making: Predictive maintenance provides companies with real-time data and insights, enabling them to make informed decisions about maintenance activities and resource allocation.

Conclusion

The role of technology in predictive maintenance is transforming the industry, enabling companies to improve maintenance efficiency, reduce costs, and enhance overall equipment reliability. By leveraging IIoT, AI, ML, and other advanced technologies, companies can detect potential equipment failures before they occur, reducing downtime and improving safety.

As the use of technology in predictive maintenance continues to evolve, companies must stay at the forefront of innovation, adopting new tools and techniques to stay competitive. By doing so, companies can unlock the full potential of predictive maintenance, achieving significant cost savings, improving maintenance efficiency, and enhancing overall equipment reliability.